When it comes to plastic manufacturing processes, thermoforming and injection molding are two of the most widely used methods. While both processes can produce high-quality plastic products, there are some key differences to consider when deciding which method to use for your project. In this article, we will provide a comprehensive comparison of thermoforming and injection molding to help you make an informed decision.

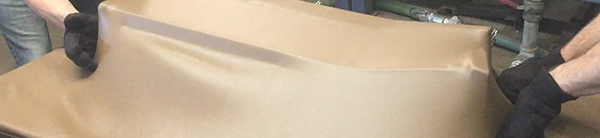

What is Thermoforming?

Thermoforming is a process that involves heating a thermoplastic sheet and then stretching it over a mold. The plastic sheet is heated to a pliable temperature and then vacuumed or pressure formed to take on the shape of the mold. This process is ideal for creating large, thin-walled parts with complex geometries.

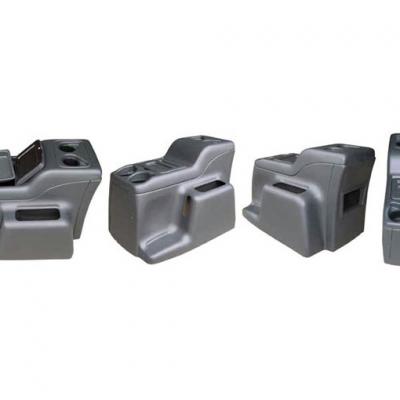

What is Injection Molding?

Injection molding is a process that involves melting plastic pellets and injecting the molten plastic into a mold. Once the plastic cools and solidifies, it is ejected from the mold. This process is ideal for creating small to medium-sized, highly detailed parts with uniform wall thicknesses.

Comparison of Thermoforming and Injection Molding Cost

Thermoforming is generally considered to be a more cost-effective process than injection molding, especially for large, complex parts. Thermoforming molds are typically less expensive to produce than injection molds and can be made in a shorter amount of time. Injection molding, on the other hand, can be more expensive due to the cost of the mold and the need for specialized equipment.

Materials

Both thermoforming and injection molding can use a wide variety of thermoplastics, including polyethylene, polypropylene, PVC, and polycarbonate. However, injection molding is better suited for materials that require tight tolerances and uniform wall thicknesses, while thermoforming can handle more flexible materials and large parts with varying wall thicknesses.

Design Flexibility

Thermoforming allows for more design flexibility than injection molding, especially when it comes to creating complex, large parts. Thermoforming can also produce parts with undercuts, which are difficult to achieve with injection molding. Injection molding, however, is better suited for creating parts with fine details and precise features.

Production Volume

Injection molding is generally better suited for high-volume production runs, while thermoforming is better suited for lower volume runs. Thermoforming can still produce a large number of parts, but the process can be slower than injection molding due to the need for heating and cooling cycles.

Lead Times

Thermoforming molds can be produced more quickly than injection molds, which can lead to shorter lead times for thermoformed parts. However, the thermoforming process itself can be slower than injection molding due to the need for heating and cooling cycles.