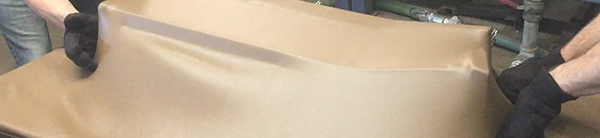

CNC routing is a powerful tool in the world of manufacturing, allowing for precision cutting of materials to create complex shapes and patterns. In the thermoforming industry, CNC routing is used extensively in the creation of 3-dimensional molds for plastic parts. In this article, we'll explore the benefits of CNC routing in 3-dimensional mold making.

Precision Cutting

CNC routing provides precise cutting capabilities, allowing for the creation of molds with intricate details and complex shapes. The use of computer-aided design (CAD) software ensures that the cutting is precise and accurate, resulting in high-quality molds that can produce accurate parts.

Faster Prototyping

CNC routing allows for faster prototyping and tooling design, reducing the time and cost required for mold making. The use of 3D modeling software allows for the creation of detailed designs that can be easily converted to CNC programs, streamlining the mold making process and reducing lead times.

Versatility

CNC routing is a versatile process that can work with a wide range of materials, including wood, plastics, and metals. This versatility allows for the creation of molds for a variety of applications, including automotive, aerospace, and consumer goods.

Complex Geometry

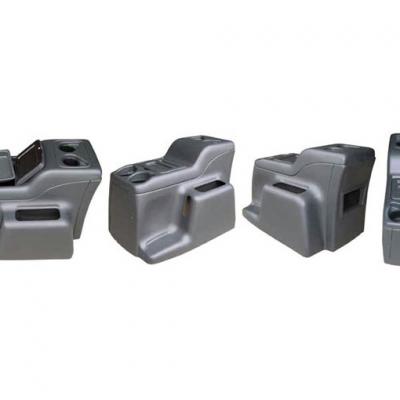

CNC routing allows for the creation of molds with complex geometries that would be difficult or impossible to achieve with traditional machining methods. This enables manufacturers to create complex parts with intricate details, improving the functionality and aesthetics of the final product.

Customization

CNC routing allows for customization of molds, ensuring that each mold is tailored to the specific needs of the application. This customization enables manufacturers to create molds that are optimized for specific parts, improving the overall quality and performance of the final product.

Conclusion

CNC routing is a powerful tool in the world of 3-dimensional mold making, providing precision cutting capabilities, faster prototyping, versatility, the ability to create complex geometries, and customization. These benefits make CNC routing an essential process in the thermoforming industry, enabling the creation of high-quality molds for a wide range of applications. If you're interested in CNC routing capabilities for your thermoforming needs, consider Salient Designs. We offer a range of CNC routing capabilities that can be tailored to meet your specific needs and requirements. Contact us today to learn more about our capabilities and how we can assist you in creating high-quality molds for your thermoforming needs.