As the world becomes more environmentally conscious, businesses are looking for ways to reduce their carbon footprint and make their operations more sustainable. One way that companies can do this is by using thermoforming, a plastic manufacturing process that is more eco-friendly than other options. In this article, we'll explore how thermoforming can help reduce your company's carbon footprint.

Thermoforming Uses Less Material

Thermoforming is a process that involves heating a plastic sheet and then forming it into a specific shape using a mold. This process uses less material than other plastic manufacturing processes, such as injection molding. This is because thermoforming only uses the exact amount of material needed for each part, which means there is less waste.

Thermoforming is Energy-Efficient

Thermoforming is also an energy-efficient process. Unlike injection molding, which requires large amounts of energy to heat and cool the mold, thermoforming only requires energy to heat the plastic sheet. This means that thermoforming can be up to 50% more energy-efficient than injection molding.

Thermoforming is Recyclable

Another benefit of thermoforming is that it is a recyclable process. The plastic used in thermoforming is typically made from high-density polyethylene (HDPE) or polypropylene (PP), both of which are recyclable materials. This means that any waste generated during the thermoforming process can be recycled, reducing the amount of waste that ends up in landfills.

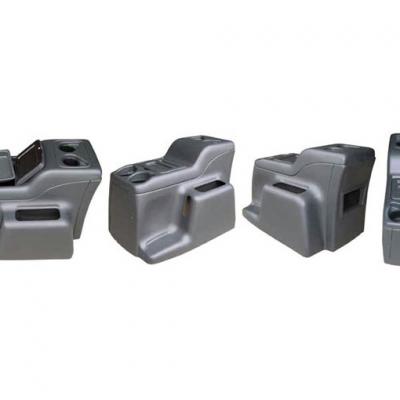

Thermoforming Creates Durable Products

Thermoforming creates durable plastic products that have a long lifespan, which reduces the need for replacements and ultimately reduces waste. Thermoformed plastic products can also be made with recycled material, further reducing the carbon footprint.

Thermoforming Uses Renewable Energy

Finally, thermoforming can be powered by renewable energy sources such as wind, solar, and hydroelectric power. By using renewable energy sources, companies can reduce their carbon footprint even further and make their operations more sustainable.

Conclusion

Thermoforming is a versatile plastic manufacturing process that can help companies reduce their carbon footprint. By using less material, being energy-efficient, creating durable products, and using recyclable materials and renewable energy sources, thermoforming can make a significant impact on a company's sustainability efforts. If you're looking for a more eco-friendly option for your plastic manufacturing needs, consider thermoforming.