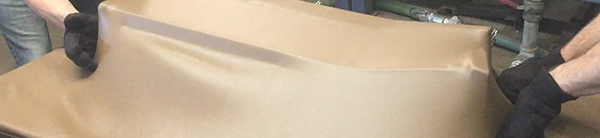

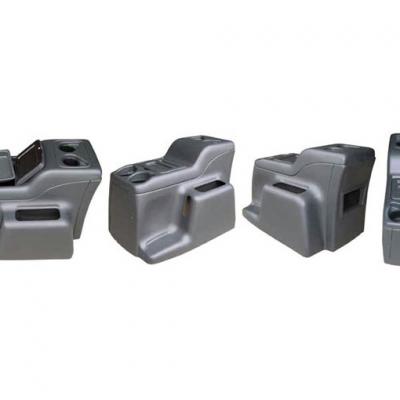

Thermoforming is a plastic manufacturing process that involves heating a plastic sheet and forming it into a specific shape using a mold. To ensure that your thermoformed parts are of high quality and meet your design specifications, it's important to consider the design of your part from the outset. In this article, we'll explore some best practices and tips for designing parts for thermoforming.

Consider Material Thickness

When designing parts for thermoforming, it's important to consider the thickness of the plastic material that will be used. Material thickness can impact the strength, flexibility, and appearance of a thermoformed part. To ensure that your part is strong and durable, while still maintaining a pleasing appearance, it's important to choose the right material thickness for your specific application.

Provide Draft Angles

Draft angles are essential for thermoformed parts, as they allow the part to be easily removed from the mold. When designing your part, be sure to provide draft angles on all sides of the part. The ideal draft angle will depend on the geometry of the part, but a general rule of thumb is to provide a draft angle of at least 1 degree for every inch of depth.

Avoid Undercuts

Undercuts are areas of a part that are difficult or impossible to remove from the mold without damaging the part. When designing parts for thermoforming, it's important to avoid undercuts or design them in a way that allows for easy removal. This can be accomplished by creating slides or other features that allow the part to be removed from the mold without damaging the part.

Design for Uniform Wall Thickness

To ensure that your thermoformed part has uniform strength and appearance, it's important to design the part with uniform wall thickness. Parts with varying wall thicknesses can be more prone to warping or cracking, and may not meet the required specifications for your application.

Consider the Mold Size

When designing parts for thermoforming, it's important to consider the size of the mold that will be used to create the part. The mold size can impact the cost of the mold, as well as the overall cost of the part. To keep costs down, it's important to design parts that can be produced using standard mold sizes whenever possible.

Test Your Design

Before committing to full-scale production, it's important to test your thermoformed part design. This can be accomplished by creating a prototype or by using computer-aided design (CAD) software to simulate the thermoforming process. By testing your design, you can identify any potential issues and make any necessary changes before moving on to production.

Conclusion

Designing parts for thermoforming requires careful consideration of material thickness, draft angles, undercuts, wall thickness, mold size, and testing. By following these best practices and tips, you can ensure that your thermoformed parts are of high quality, meet your design specifications, and are cost-effective to produce. If you're new to thermoforming, consider working with an experienced thermoforming partner who can guide you through the design process and help you achieve your goals.