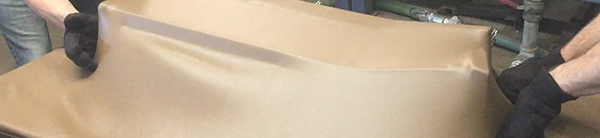

Thermoforming is a plastic manufacturing process that involves heating a plastic sheet and forming it into a specific shape using a mold. While thermoforming is used in a wide range of industries, it has particular benefits for the marine industry. In this article, we'll explore how thermoformed plastics can benefit the marine industry.

Corrosion Resistance

One of the main benefits of thermoformed plastics for the marine industry is their resistance to corrosion. Marine environments are particularly harsh, with exposure to saltwater, sunlight, and other elements. Thermoformed plastics, particularly those made from materials such as PVC or acrylic, are highly resistant to corrosion and can withstand prolonged exposure to these elements.

Customization

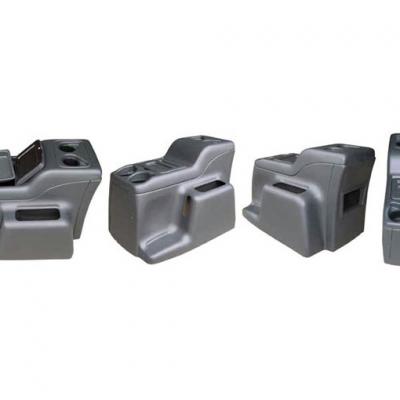

Thermoformed plastics can also be easily customized to meet the specific design requirements of each marine vessel. Unlike metal, which requires specialized equipment and processes to customize, thermoformed plastics can be easily shaped and formed into a variety of shapes and sizes. This allows for greater design flexibility and the ability to create unique marine parts and components.

Lightweight

Another benefit of thermoformed plastics for the marine industry is that they are lightweight. This is particularly important for vessels such as boats, where weight can impact performance and fuel efficiency. Thermoformed plastics are much lighter than many traditional marine materials, such as metal or fiberglass, making them an attractive option for boat builders.

Durability

Thermoformed plastics can also offer improved durability over other materials. Thermoformed parts can be designed to be impact-resistant, and they can also withstand exposure to harsh environments, such as extreme temperatures, UV rays, and chemicals. This makes them ideal for use in marine parts that are exposed to harsh conditions.

Reduced Maintenance

Thermoformed plastics can also offer reduced maintenance over other materials. Unlike metal, which can corrode and require frequent maintenance, thermoformed plastics are highly resistant to corrosion and can require less maintenance over time. This can lead to cost savings for marine vessel owners, as well as increased time on the water.

Conclusion

Thermoformed plastics offer many benefits for the marine industry, including corrosion resistance, customization, lightweight, durability, and reduced maintenance. As marine vessel owners and builders seek ways to improve the performance, efficiency, and durability of their vessels, thermoformed plastics will likely continue to play a key role in the industry. If you're looking for a lightweight, durable, and customizable option for your marine parts and components, consider thermoforming.