Custom conversions are a popular way for individuals and businesses to create unique vehicles that meet specific needs or preferences. Whether it's converting a van into a mobile office or a truck into a mobile workshop, custom conversions require a high degree of customization and attention to detail. Thermoforming is a cost-effective and efficient way to create custom parts and components for vehicle conversions. In this article, we'll explore the benefits of thermoforming in maximizing efficiency in vehicle custom conversion.

Customization

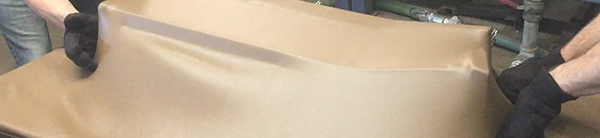

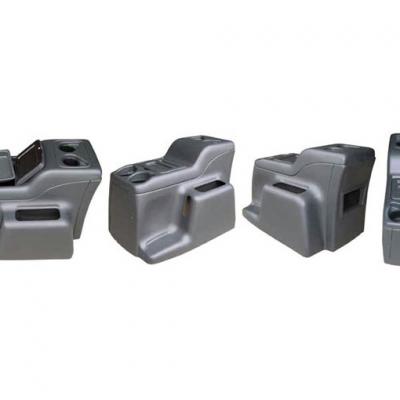

Vehicle conversions require a high degree of customization to meet specific needs and preferences. Thermoforming offers a high degree of design flexibility, allowing for the creation of custom parts and components that meet unique design requirements. Thermoforming is particularly beneficial for creating complex shapes and designs that may not be possible with other manufacturing methods. This customization allows for the creation of unique vehicles that stand out from the crowd.

Cost-Effective

Thermoforming is a cost-effective manufacturing method, particularly for smaller production runs. The cost of thermoforming molds is typically lower than that of injection molding or other manufacturing methods, making it a more affordable option for producing custom parts and components for vehicle conversions. Additionally, thermoforming is a more efficient process, allowing for faster production runs at a lower cost per part.

Durability

Vehicle conversions often require parts and components that are durable and long-lasting. Thermoformed parts and components are known for their durability, making them an ideal solution for vehicle conversions. Thermoforming allows for the use of high-strength materials that can withstand wear and tear, ensuring that the parts and components can withstand even the most challenging working conditions.

Versatility

Thermoforming is a versatile process that can be used to create a wide range of parts and components for vehicle conversions. These include but are not limited to, interior and exterior panels, door panels, dashboards, and storage compartments. Thermoforming is also ideal for creating custom storage solutions, such as compartments and organizers, that can be tailored to fit specific vehicles and applications.

Improved Lead Times

Thermoforming is a fast process, making it ideal for vehicle conversions. Thermoforming molds can be produced quickly, allowing for faster production runs. Additionally, the thermoforming process itself is generally faster than other manufacturing methods, allowing for larger quantities of parts and components to be produced in a shorter amount of time. This improved lead time is particularly beneficial for individuals and businesses that require quick turnarounds.

Conclusion

Thermoforming is an ideal solution for maximizing efficiency in vehicle custom conversion, offering benefits such as customization, cost-effectiveness, durability, versatility, and improved lead times. If you're considering a vehicle conversion, consider thermoforming as a cost-effective and efficient manufacturing method. Salient Designs is an experienced thermoforming company that can help you bring your ideas to life. Contact us today to learn more about our capabilities and how we can assist you in creating custom parts and components for your vehicle conversion.