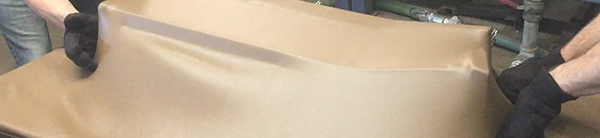

Thermoforming is an ideal solution for creating custom plastic components for HVAC systems. The process is fast, efficient, and can produce parts with complex geometries. In this article, we'll explore how thermoforming is used in the HVAC industry to create cost-effective and efficient solutions.

Custom Design

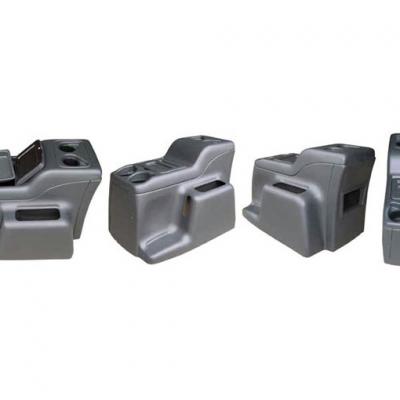

Thermoforming allows for the creation of custom designs that meet the unique needs of the HVAC industry. Thermoformed products can be designed to fit specific HVAC systems, ensuring a perfect fit and maximum functionality. Custom designs can also be created for specific applications, such as ductwork, vent covers, and air distribution components.

Lightweight Materials

Thermoforming is an ideal solution for creating lightweight materials in the HVAC industry. Materials such as ABS, polycarbonate, and acrylic are commonly used in thermoforming, providing a lightweight alternative to metal and other heavier materials. The use of lightweight materials reduces the weight of the HVAC systems, improving energy efficiency and reducing operating costs.

Durable Products

Thermoformed products in the HVAC industry are known for their durability, withstanding the rigors of daily use. Thermoformed products are resistant to impact, vibration, and fatigue, ensuring that they can withstand the stresses of HVAC environments. They are also resistant to chemicals, making them ideal for use in HVAC systems.

Cost-Effective Solutions

Thermoforming provides cost-effective solutions for the HVAC industry. The use of lightweight materials reduces the weight of the HVAC systems, improving energy efficiency and reducing operating costs. Thermoforming is also a more cost-effective solution than other manufacturing methods, such as injection molding or metal fabrication.

Improved Production Time

Thermoforming provides faster production times than other manufacturing methods, allowing for quicker turnaround times for HVAC products. Thermoforming allows for the creation of large, complex shapes with minimal tooling costs, reducing the time and expense required for tooling design and manufacturing.

Conclusion

Thermoforming is an ideal solution for the HVAC industry, providing cost-effective and efficient solutions for creating custom plastic components. Thermoforming allows for the creation of custom designs that meet the unique needs of the HVAC industry, providing lightweight and durable products that are resistant to impact, vibration, and fatigue. If you're looking for thermoforming solutions for the HVAC industry, consider Salient Designs. We offer a range of thermoforming capabilities that can be tailored to meet your specific needs and requirements. Contact us today to learn more about our capabilities and how we can assist you in creating cost-effective and efficient solutions for your HVAC applications.