Utility vehicles have become increasingly popular in recent years, with their versatility and practicality making them an essential tool for many industries. However, finding replacement parts and accessories for these vehicles can be challenging, especially if they are no longer in production. This is where thermoforming comes in. Thermoforming offers a cost-effective and efficient way to create custom parts and accessories for utility vehicles. In this article, we'll explore the benefits of thermoforming solutions for the utility vehicle aftermarket.

Cost-Effective

Thermoforming is a cost-effective manufacturing process, particularly for smaller production runs. The cost of thermoforming molds is typically lower than that of injection molding or other manufacturing methods, making it a more affordable option for producing custom parts for utility vehicles. Additionally, thermoforming is a more efficient process, allowing for faster production runs at a lower cost per part.

Customization

Utility vehicles often require custom parts and accessories to meet specific needs or requirements. Thermoforming offers a high degree of design flexibility, allowing for the creation of complex shapes and designs. This flexibility is particularly beneficial for creating custom parts and accessories for utility vehicles, as it allows for the creation of parts that meet unique design requirements. Thermoforming also allows for the use of a wide range of materials, including recycled and sustainable materials.

Durability

Utility vehicles are often subjected to harsh working conditions, which means that the parts and accessories used in these vehicles must be durable and long-lasting. Thermoformed parts and accessories are known for their durability, making them an ideal solution for the utility vehicle aftermarket. Thermoforming allows for the use of high-strength materials that can withstand wear and tear, ensuring that the parts and accessories can withstand even the most challenging working conditions.

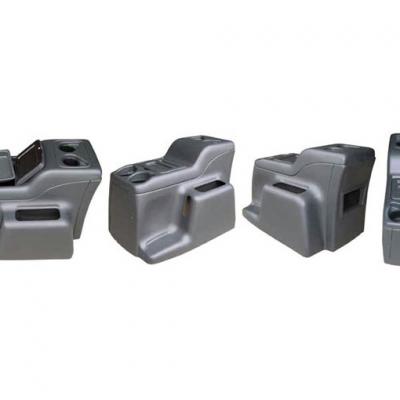

Versatility

Thermoforming is a versatile process that can be used to create a wide range of parts and accessories for utility vehicles. These include but are not limited to, thermoformed tops, floor mats, dashboards, door panels, and cargo liners. The process is also ideal for creating custom storage solutions, such as compartments and organizers, that can be tailored to fit specific vehicles and applications.

Improved Lead Times

Thermoforming is a fast process, making it ideal for the production of parts and accessories for the utility vehicle aftermarket. Thermoforming molds can be produced quickly, allowing for faster production runs. Additionally, the thermoforming process itself is generally faster than other manufacturing methods, allowing for larger quantities of parts to be produced in a shorter amount of time.

Conclusion

Thermoforming is an ideal solution for the utility vehicle aftermarket, offering benefits such as cost-effectiveness, customization, durability, versatility, and improved lead times. If you're looking to create custom parts or accessories for your utility vehicle, consider thermoforming as a cost-effective and efficient manufacturing method. Salient Designs is an experienced thermoforming company that can help you bring your ideas to life. Contact us today to learn more about our capabilities and how we can assist you in creating custom parts and accessories for your utility vehicle.